EKOSTAR FLOW V BASIC LINE

Laminar flow cabinets with vertical airflow

In the BASIC LINE configuration, these cabinets are intended for customers that prefer a simpler manual design with manual controls but also demand a higher level of finish, level of options, a modern solution and the representative design offered by our top-of-the-line cabinets.

EXTENSIVE STANDARD EQUIPMENT

EKOSTAR FLOW V laminar flow cabinets in the BASIC LINE configuration contain above-standard equipment. Heavier duty controls, antibacterial and retractable front safety glass with a warning system to indicate proper working position, an out of sight UV lamp integrated into the workspace in a position that does not disturb laminar flow, LED lighting that imitates daylight for perfect visibility, electrical sockets inside and outside the workspace, enhanced electrical safety with a current protection device and preparation for a gas, water or vacuum connection are all standard. The system records the operating time for the overall equipment and individually for the filters and the UV lamp. These values are shown on a 2.5” full-graphic LCD display next to the controls. The system is equipped with a functional acoustic and visual filter status alarm.

Preset laminar flow and perfect working conditions in the workspace are also provided by the intake fan that drives the aseptically clean air into the workspace and the creation of a vertical air tunnel that completely isolates the workspace from the external environment.

The cleaning and disinfection of EKOSTAR FLOW H laminar flow cabinets is quick and easy thanks to the continuous stainless steel worktop with enhanced chemical and mechanical resistance and the special powder coating, which minimizes the risk of contamination and provides higher resistance to abrasion.

- Manual controls in the lower part of the top cover using stainless steel, vandalism resistant back-lit rocker switches (separate for filtration, mode selection, lighting and the UV lamp)

- Integrated UV lamp (IP65) located out of sight in the top and in a position that does not interfere with the laminar flow

- The LED lighting in the workspace is a neutral white color

- 3/8” preparation for a water, gas or vacuum connection (1 for V550 and V800 / 3 for V1050, V1300, V1550 and V1800)

- Two operating regimes – ENERGY EFFICIENT (SAVING) AND OPERATING (NORMAL)

- 230 V electrical socket (IP55) in the workspace (1x for V550, V800 and V1050 / 2x for V1300, V1550 and V1800)

- 230 V power socket (IP55) outside the workspace (1x)

- Current protection device for greater electrical safety

- Acoustic and visual filter status alarm

- Hour counter for the filters, equipment and UV lamp with data shown on a 2.5” LCD display located on the front cover (next to the controls)

- G4 class pre-filter on the inlet to extend the service life of the primary filters

- Class U15 absolute ULPA filter in an aluminum frame offering 99.9995% efficiency for particulate measuring 0.3 µm on the inlet

- Manually adjustable safety glass with no angle and with a defined workspace and mechanical warning to ensure the positioning in the correct working position

- Stainless steel worktop with an enhanced chemical and mechanical resistance (AISI 316L), continuous surface, matte finish to prevent glare

- Laminarizing stainless steel grid

- Safety glass used in all glazing, 6 mm thick with antibacterial finish

- One fan – an intake fan to create an aseptically clean environment in the workspace

- Inert powder coating surface finish to minimize the risk of contamination

- Removable storage shelf integrated in the pedestal underneath the worktop (only for versions with a pedestal)

- Removable storage space in the bottom of the pedestal (only for versions with a pedestal)

- Replacement filter elements for one year of operation at no charge (pre-filter)

- Pedestal in the mobile configuration with brakes (not height-adjustable)

- Gas supply valve

- Water supply valve

- Vacuum supply valve

- 1x additional 230 V electrical socket (IP55) in the workspace (not available on V550 or V800 models)

- 2x additional 230 V electrical sockets (IP55) in the workspace (not available on V550, V800 or V1050 models)

- Practical universal bushings on the side glass for routing the power cables of the external equipment outside of the workspace (only for versions with glazed sides)

- UV lamp timer

- Ergonomic hand rest

- Foot rest

- Full stainless-steel cabinet

- Full stainless-steel cabinet + RAL

PERFECTLY PRACTICAL

The manual configuration of EKOSTAR FLOW V laminar flow cabinets is characterized by the simplicity of control and the ability to work in two modes:

1) OPERATING (NORMAL) - designed for full-time work in the workspace

2) ENERGY EFFICIENT (SAVING)- designed to provide the most energy efficient operations and to keep an aseptically clean environment if work must be interrupted.

The ability to work in the two modes specified above in combination with the manual configuration and simple manual controls makes working with these cabinets efficient, easy and convenient.

Customers may select from a broad range of sizes, from small cabinets to cabinets that are up to 1800 mm wide. All types of EKOSTAR FLOW V cabinets are designed for installation on height-adjustable pedestals with storage space direct from the manufacturer or on a table that the customer currently has that meets the specifications in terms of load rating and dimensions. These pedestals permit working in seated and standing positions. Bases may also be provided in a mobile configuration upon request.

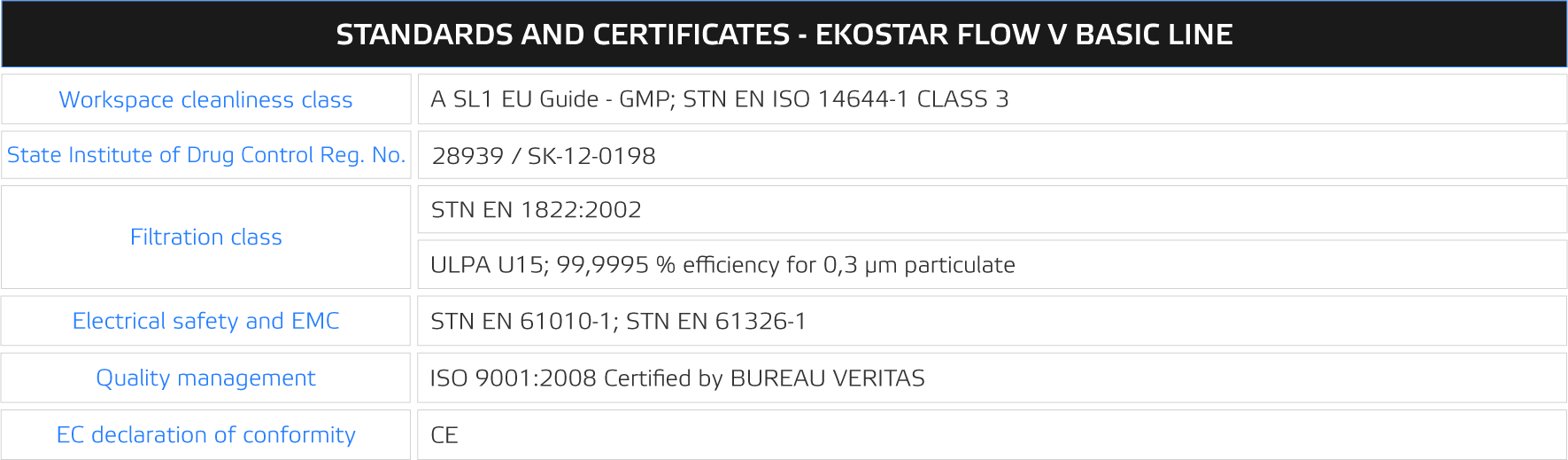

ULPA FILTRATION STANDARD

EKOSTAR FLOW V BASIC LINE laminar flow cabinets are automatically equipped with the latest generation class U15 high efficiency ULPA filters capable of removing particulate as small as 0.1 µm. The class of ULPA filters used in this design is characterized by a much higher level of filtration than standard HEPA filters. The cabinets are also equipped with class G4 mechanical pre-filtration used to capture larger particulate and contaminants, which ensures a longer service life for the primary filters.

All aseptic EKOSTAR FLOW V BASIC LINE cabinets automatically achieve ISO CLASS 5 air purity as the standard. The unique design and selected filter mean they meet the demanding air purity criteria defined in ISO CLASS 3 thanks to which they are destined forthe most demanding applications.

Customers have the option to complete their cabinets with an extensive range of extra equipment, choose a different color version or adapt the equipment to their specific needs using the YourBox program.

We provide a standard 2-year warranty for our equipment. This warranty may be extended by up to 5 years with regular care!

Each manufactured model is subject to an automatic final functionality check using validation measurements with a validation certificate provided as evidence of its completion.

Please contact us directly or use our configurator to define the exact specifications for your cabinet.

Contact ConfiguratorIT PAYS TO CARE FOR YOUR CABINET

Our cabinets are closely related to safety and therefore maintenance is necessary to keep them in perfect technical condition throughout their operation. We as the manufacturer are concerned with their proper operation and therefore recommend regular checks of their technical condition and functional verification through professional service inspections. We also recommend changing all of the filters at the regular recommended intervals.

If you decide to perform regular service checks during the first five years after the sale of the equipment, we’ll reward you for caring for YOUR equipment, YOUR health and YOUR product with a 5-year warranty!

Service inspections are voluntary, but critical for proper functionality given the character and the use of the equipment. We recommend conducting them at regular intervals. They protect your people, your products and your interests!

YOU SET THE LENGTH OF YOUR WARRANTY

If the recommended service inspections are performed annually over the first five years of operation, we’ll provide your equipment with a warranty covering 5 years from the date of purchase!

The total length of the warranty depends on the number of service inspections performed on your equipment (the warranty is extended by one year for the first and then every subsequent inspection, up to a maximum of 5 years)

We want to be fair, and that’s why we openly declare that inspections are voluntary and a paid service. However, inspections and filter replacement give you 100% certainty that the product will continue to operate properly and that your work processes and users are safe, which we confirm with a functional test or validation at the end of every service inspection. We extend our warranty as a reward for the care this equipment needs anyway!

CAREFREE SERVICE

If you decide on a regular maintenance program, you no longer need to worry about when the last inspection was performed or when the next one is scheduled. We’ll monitor it for you! We’ll be sure to notify you well in advance.One less worry for you.

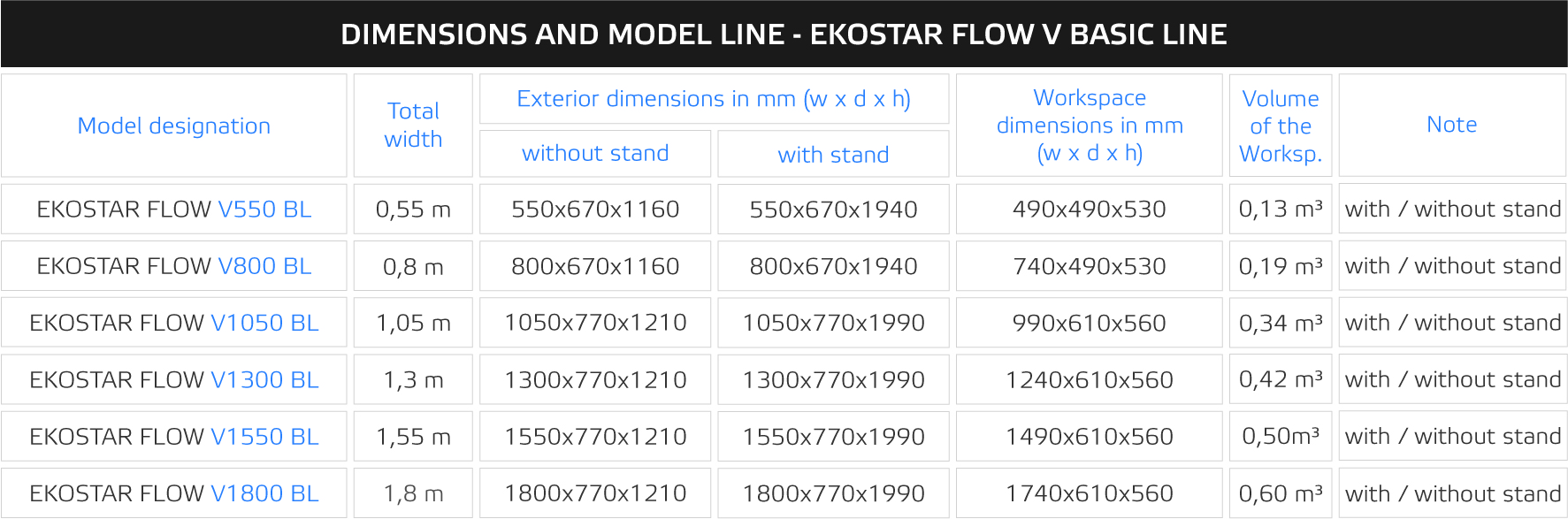

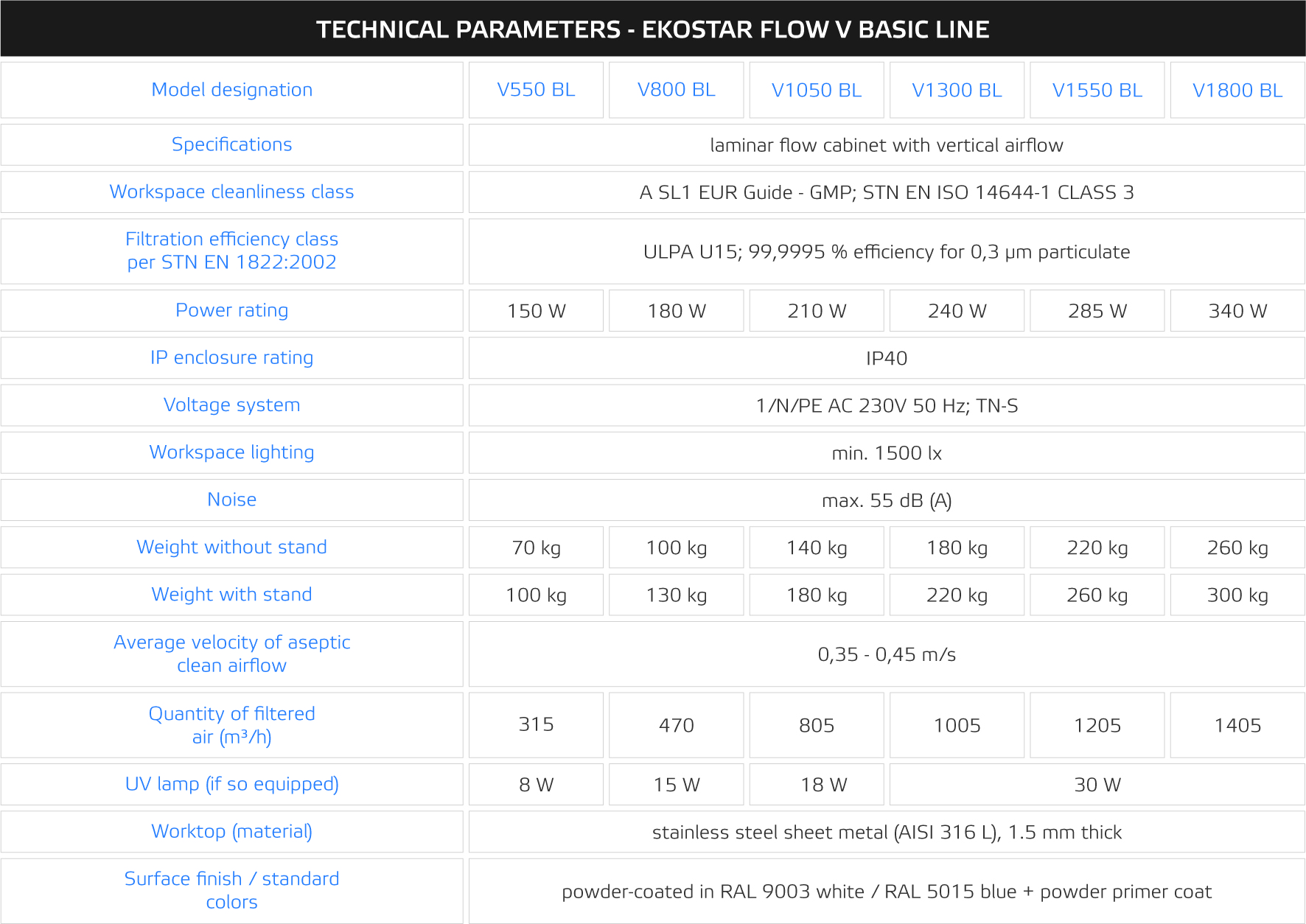

MODEL LINE