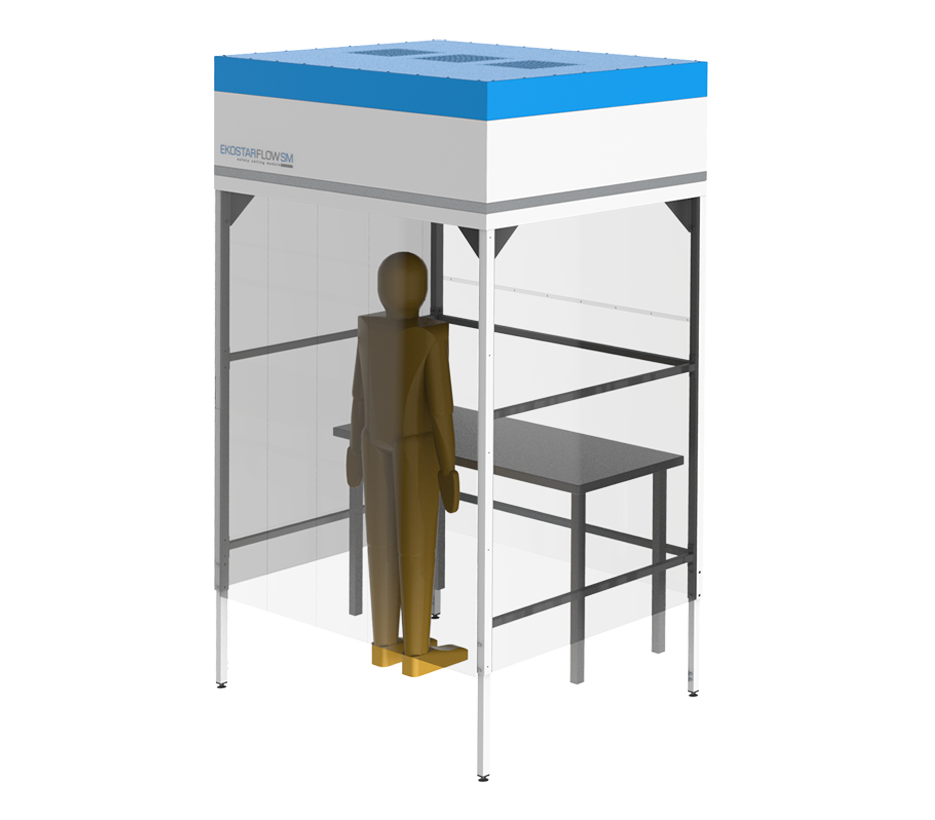

EKOSTAR FLOW SM

Laminar flow ceiling modules with vertical airflow

EKOSTAR FLOW SM laminar flow ceiling modules are suspended modular boxes with vertical laminar airflow providing protection for a processed product or material from bacteriological or particulate contamination from the outside environment. This type of cabinet does not protect the user from any harmful effects of the processed substances or materials.

These ceiling modules may be used wherever work operations need to be conducted in an aseptically clean or dust-free environment without the need to protect personnel from the effects of the materials worked on inside the spaces defined by these modules. They may also be used anywhere there is a need to eliminate the vibrations caused by the operation of the laminar flow cabinets and where size restrictions prevent the use of laminar flow cabinets. This equipment has a broad range of applications in health care, pharmaceuticals, life sciences, the food industry, electronics, optics, precision mechanics, etc.

EKOSTAR FLOW SM ceiling modules are characterized by their premium processing and, thanks to their unique construction and the use of components and materials from world-renowned manufacturers, they deliver extraordinary reliability, low noise, low power consumption, long filter life and also high filtration efficiency. Thanks to laminar flow in a vertical direction and a carefully selected filter assembly, they provide complete protection of the work process conducted inside the workspace.

All EKOSTAR FLOW SM ceiling modules are custom made in the YourBox program to the customer’s individual specifications using either standard steel, with a powder-coated surface finish in an RAL color of choice, or stainless steel.

Our ceiling modules achieve ISO CLASS 5 air purity as the standard. Other levels of efficiency (from ISO CLASS 3 to ISO CLASS 8) may be achieved depending on customer specifications or the class of the specific filters used in the modules.

UNIVERSAL CUSTOM SOLUTION

Ceiling modules are easy to install over an entire workstation or production line, either by integrating them into a frame structure that defines the overall workspace or by anchoring the modules to the ceiling in the space. The internal workspace underneath the ceiling modules is separated from the outside using PVC films or, when the modules are installed on a structure with solid partitions, another material per the customer’s individual specifications. Ceiling modules create an aseptically clean or dust-free environment characterized by laminar airflow that is completely isolated from the outside environment. As opposed to laminar flow cabinets, users may operate directly inside the defined workspace when ceiling modules are used, or even an entire production line can be enclosed.

An advantage offered by EKOSTAR FLOW SM ceiling modules is the ability to adapt them to various size requirements to cover the entire area necessary. If a large workspace must be covered and a single module is insufficient, multiple modules may be combined and connected to cover any size space as needed. Control over the modules in this case is performed centrally by connecting all the units in a chain.

ULPA FILTRATION STANDARD

Modules come standard with class U15 ULPA filters capable of removing particulate as small as 0.1 µm. The class of ULPA filters used in this design is characterized by a higher level of filtration than standard HEPA filters. Upon customer request, ceiling modules may be equipped with filters of other efficiency classes. Modules are also equipped with mechanical pre-filters used to capture larger particulate and contaminants, which ensures a longer service life for the primary filters. They may also be equipped with an additional electrostatic module to disinfect the intake air.

BROAD RANGE OF OPTIONS

Customers may choose between manual and fully automated microprocessor-controlled ceiling modules. In both instances, fan output is controlled at multiple stages, which allows airflow speeds to be changed as needed in a range that always ensures laminar flow. The controller in the automated version of the ceiling module controls fan output depending on the filter condition to ensure the operator-defined airflow speed is always maintained. Modules are equipped with a full-color touchscreen LCD display to control the module and monitor operating parameters, including filter condition and service life. Ceiling modules come with standard and other specific options depending on the needs and specifications of the customer.

We provide a standard 2-year warranty for our equipment. This warranty may be extended by up to 5 years with regular care!

Each manufactured model is subject to an automatic final functionality check using validation measurements with a validation certificate provided as evidence of its completion.

Please feel free to contact us to custom design a ceiling module and a custom quotation for you here:

ContactIT PAYS TO CARE FOR YOUR CABINET

Our cabinets are closely related to safety and therefore maintenance is necessary to keep them in perfect technical condition throughout their operation. We as the manufacturer are concerned with their proper operation and therefore recommend regular checks of their technical condition and functional verification through professional service inspections. We also recommend changing all of the filters at the regular recommended intervals.

If you decide to perform regular service checks during the first five years after the sale of the equipment, we’ll reward you for caring for YOUR equipment, YOUR health and YOUR product with a 5-year warranty!

Service inspections are voluntary, but critical for proper functionality given the character and the use of the equipment. We recommend conducting them at regular intervals. They protect your people, your products and your interests!

YOU SET THE LENGTH OF YOUR WARRANTY

If the recommended service inspections are performed annually over the first five years of operation, we’ll provide your equipment with a warranty covering 5 years from the date of purchase!

The total length of the warranty depends on the number of service inspections performed on your equipment (the warranty is extended by one year for the first and then every subsequent inspection, up to a maximum of 5 years)

We want to be fair, and that’s why we openly declare that inspections are voluntary and a paid service. However, inspections and filter replacement give you 100% certainty that the product will continue to operate properly and that your work processes and users are safe, which we confirm with a functional test or validation at the end of every service inspection. We extend our warranty as a reward for the care this equipment needs anyway!

CAREFREE SERVICE

If you decide on a regular maintenance program, you no longer need to worry about when the last inspection was performed or when the next one is scheduled. We’ll monitor it for you! We’ll be sure to notify you well in advance. One less worry for you.